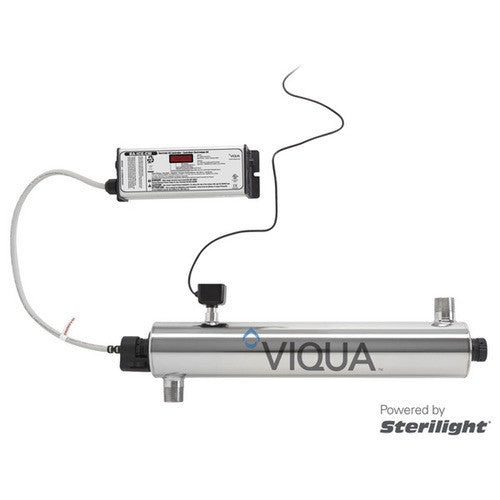

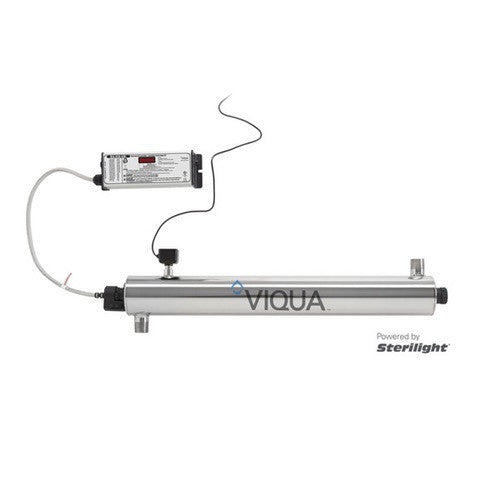

UV Water Treatment Systems

UV water treatment systems are a popular, highly effective, and easy to use way to protect your water from living organisms like bacteria, cysts such as crypto and giardia, and many viruses. UV systems are trusted by thousands of people worldwide for use in homes, cottages, and in many industrial and commercial applications. They come in a variety of sizes and can be used to purify the water for a single faucet or for an entire home or larger building. Compared to chemical water disinfection methods, UV systems are far superior because they don't add any harmful chemicals to the water, or to the environment.